Solutions we provide

Ensuring Accuracy of Outbound Packages for a Vehicle Manufacturer with Barcode Scanning and OCR

Our client is a leading supply chain solutions company in India. Typically, they dispatched parts in totes or large bins. However, they did not have a system of validating whether a tote matched their customer’s order before dispatch. This resulted in a large number of deliveries returning to the warehouse. The contractual breaches also caused significant monetary losses.

KamerAI’s barcode scanning and OCR solution helped the client reduce errors and ship packages after accurate matching.

The challenge

The client’s warehouse processed about 2000 to 3000 totes each day. Each tote had a barcode that corresponded to a product ID in the client’s system. Due to an inefficient system or sometimes human error, wrong totes would be associated with the product IDs in the warehouse. The totes would then be shipped to the customer, only to be rejected and returned.

Our client incurred considerable costs — both in corrective measures and customer satisfaction — due to this.

KamerAI’s approach

A deep learning-based solution that used barcode scanning and OCR to confirm that the totes held the right products before dispatch.

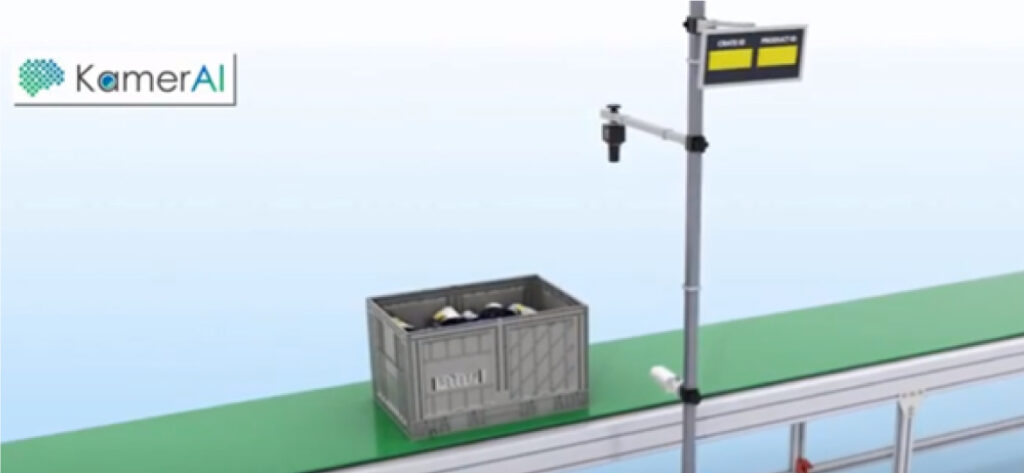

Hardware setup: The equipment consisted of two cameras, one on top and another on the side, connected to a user interface (UI). As the tote approached on the conveyor belt, the camera on the side scanned the barcode on it. The top camera read the product label inside using OCR.

Software process: KamerAI then reconciled these data points, and displayed the result on the UI integrated into the client’s ERP. The warehouse staff was alerted when the barcode and product ID did not match, so the error could be rectified.

Outcomes

- Operationally, our client reduced shipment errors and the number of returns to the warehouse.

- They also saved significantly in cost and time as fewer mistakes meant that lesser labour was directed to correcting them.

Future outlook

While the client uses a manual conveyor system now, KamerAI can be easily adapted to an automated conveyor belt when the need arises.